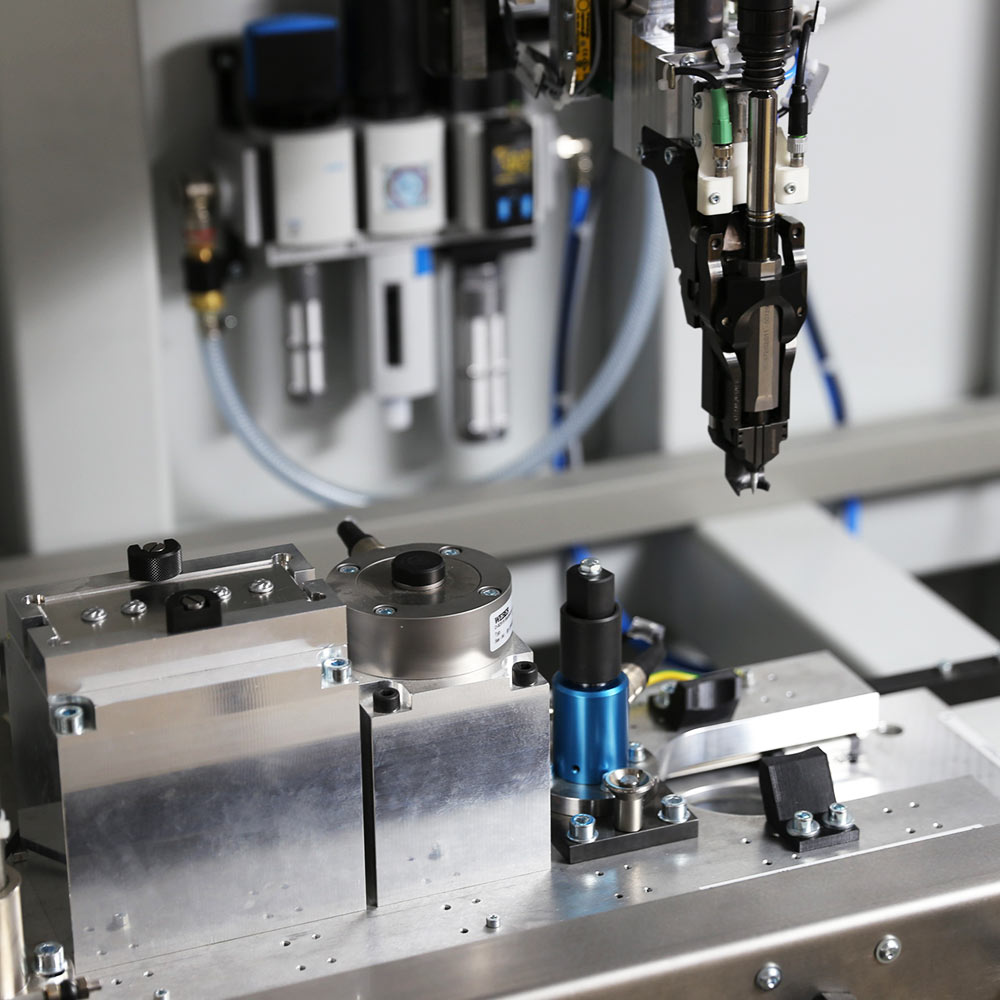

System for function testing the RSF screwdriving, feed or control systems The testing cell is used during maintenance work to ensure the quality level of our RSF systems.

The function testing system consists of a cell with a control panel and is designed for the following components and tests:

- Screwdriving tests, torque tests and force measurements of the axial force of the bit stroke and the downholder can be carried out with the RSF25 screwdriving spindles.

- The ZEL1350 feeder can be tested in conjunction with the screwdriving spindle and the controller in a continuous cycle.

- A function test of the RSF controller C50S can be carried out.