Blind rivet nuts. Efficient. Innovative.

Precision in all process steps – for durable connections! Ensure process reliability for detachable connections in any position.

Precision in all process steps – for durable connections! Ensure process reliability for detachable connections in any position.

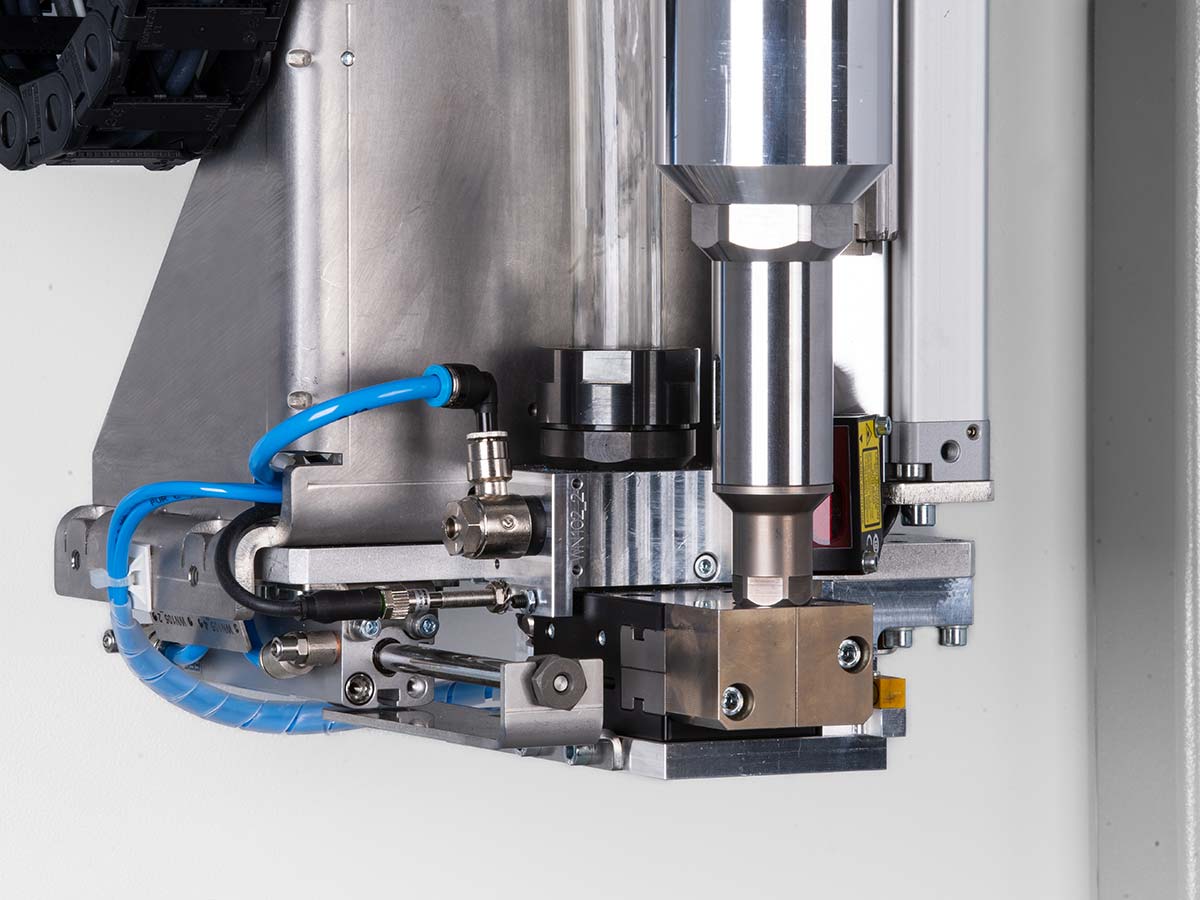

WEBER offers a system for automated inserting of blind rivet nuts and bolts that can process fasteners with round shanks or hexagonal shanks with up to 25 kN. The process control and auto feed systems are optimally adapted to the process. In addition to optinally automated changeover of the threaded mandrel, the insertion head also supports high-precision pre-alignment of hexagon fasteners to ensure maximum automation in its class. Interfaces with optional docking capability provide maximum flexibility when multiple fasteners or tools are in use.

| SBM25 | |

|---|---|

| Inserting force [kN] | up to max. 25 (continuous operation) |

| Inserting stroke [mm] | up to max.15 15 |

| Standard head stroke [mm] | approx. 100 |

| Weight [kg] | approx. 50 |

| Processable blind rivet nuts | M4 – M10 |

| Processable blind rivet bolts | M5 – M8 |

| Processable shapes | Round and hexagonal threads, different heads and types on request |

| Technical changes reserved. |

Discover solution and product information digitally. Take advantage of the WEBER E-Catalogs to quickly navigate to your destination. Everything at your fingertips, right here and now.

You can find more information about the company and the products here. Discover WEBER automatic screwdriving machines GmbH and the world of assembly line automation.

WEBER Schraubautomaten GmbH is a family-run and innovative company that attaches great importance to the sustainable design of the value chain. The result is high-quality products with maximum process reliability that make production processes more efficient. Your success is our success.