Inserting blind rivet nuts means setting single threads in a thin-walled object from one side. They are either round or hexagon nuts. In contrast to the general term “blind rivets”, where permanent fastenings are established, “blind rivet nuts” create fastenings that can be released again.

What you should know about inserting blind rivet nuts

What does setting blind rivet nuts mean

Contact us

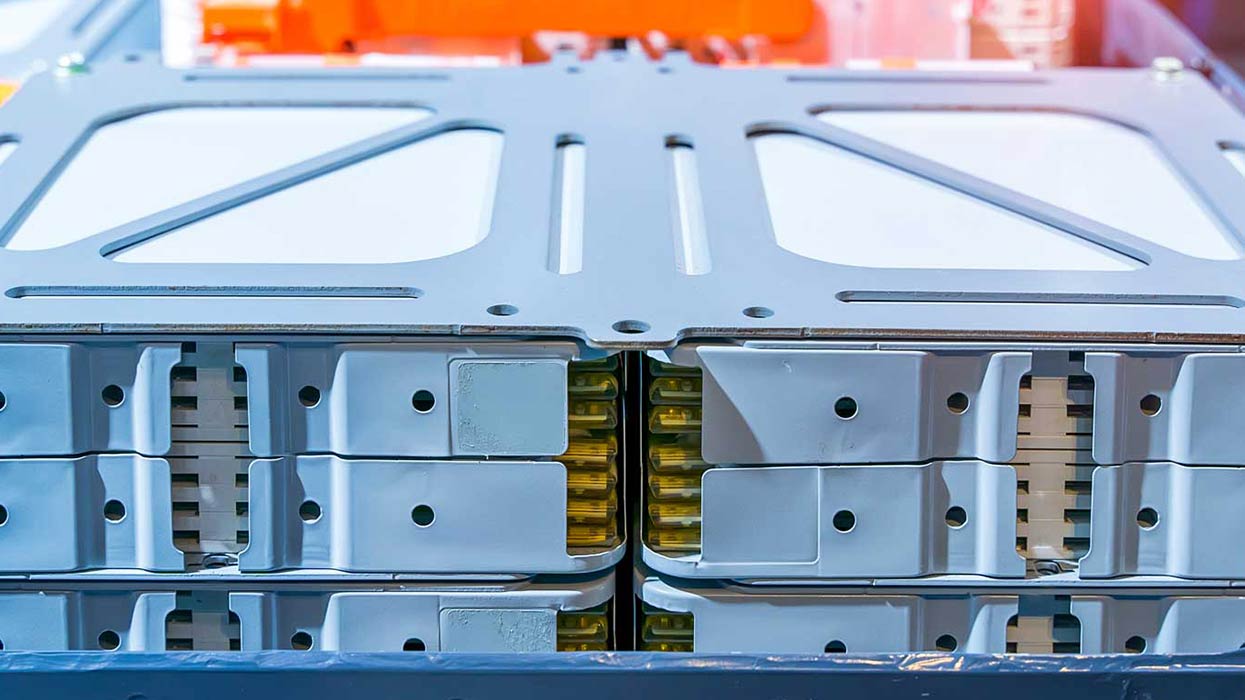

In which areas are blind rivet nuts used?

Blind rivet nuts are set primarily in the automotive and aircraft sector. Particularly lightweight materials are used in these areas to save weight. In contrast to very strong materials such as iron (machines can cut into these), other solutions are required for materials such as carbon or plastic: Blind rivet nuts are the perfect alternative for thread solutions. Blind rivet nuts are used to create detachable connections.

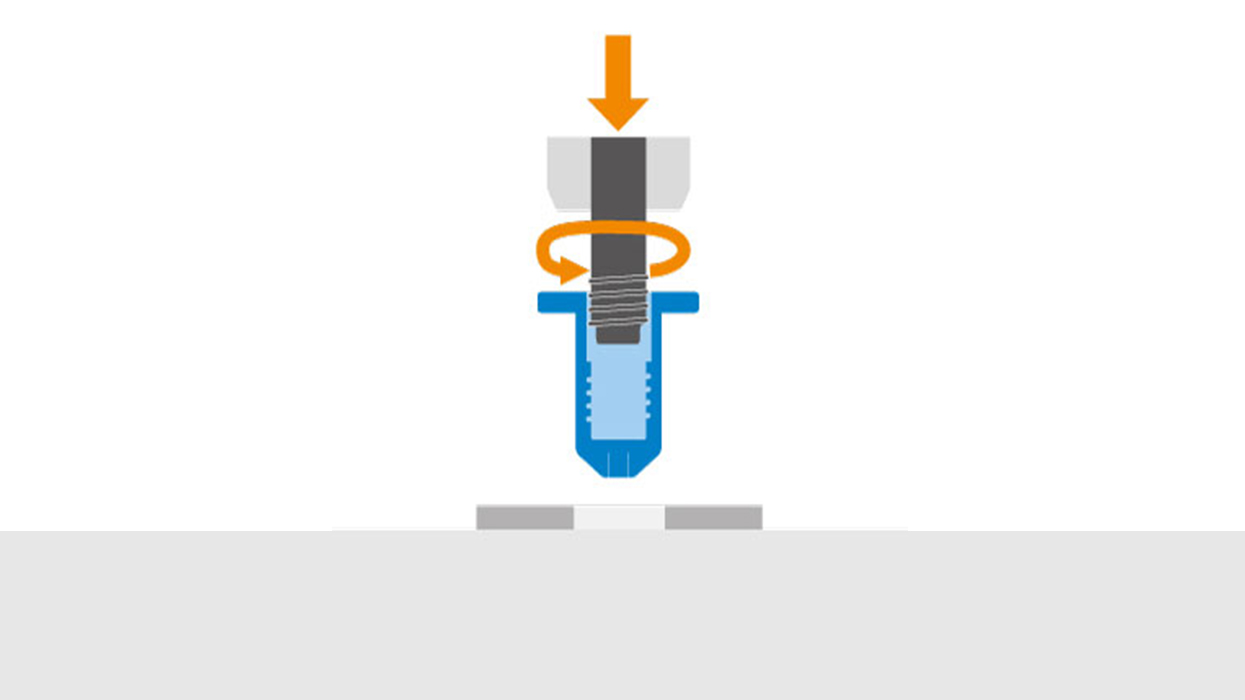

Process of inserting blind rivet nuts

Blind rivet nuts are set in 4 phases.

Phase 1: Threading and positioning the blind rivet nuts

First, the blind rivet nuts are poured into a feeding system as a bulk material and all blind rivet nuts are separated. Then each nut is blown into the inserting system individually through a hose. When the nut arrives at the inserting system, it is aligned in a small device. Then the nut is clamped.

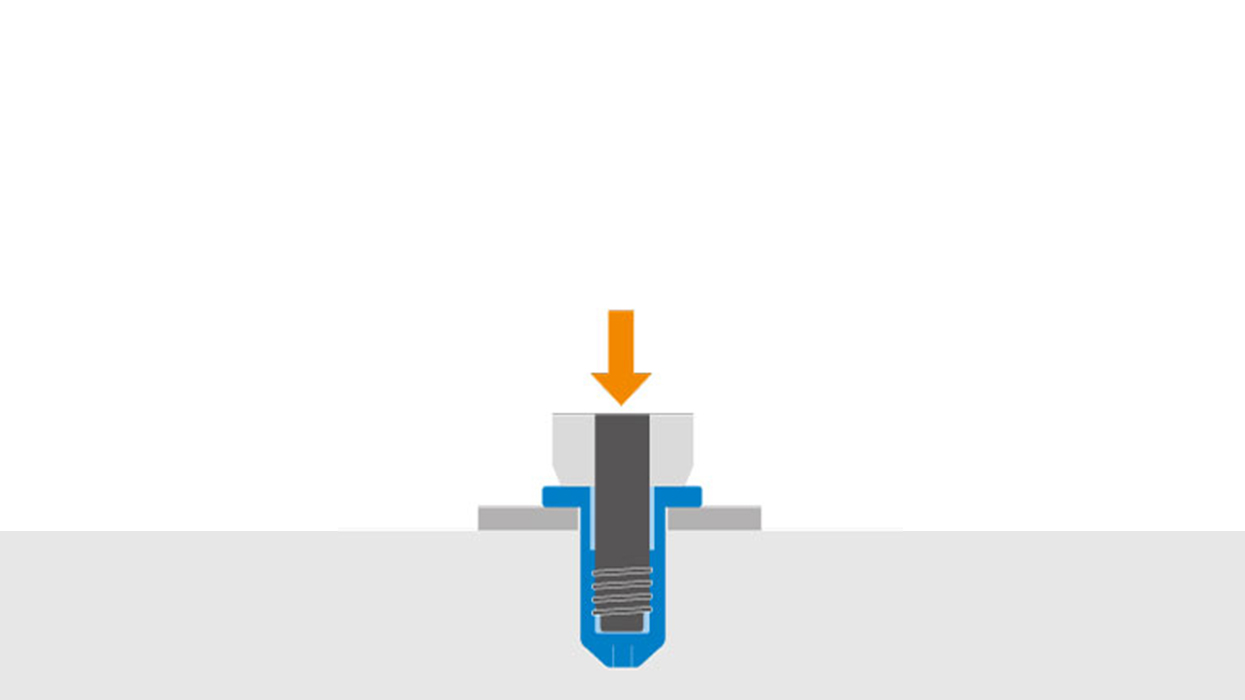

Phase 2: Feeding into the part

While the nut is threaded, nuts with a damaged thread can be detected and ejected. After correct threading and positioning, the blind rivet nut is set into the corresponding component. While positioning is not required for round nuts, hexagon nuts have to be aligned precisely. The pre-punched hole in the material is pre-defined as round or hexagon shape. Now the respective nut is positioned.

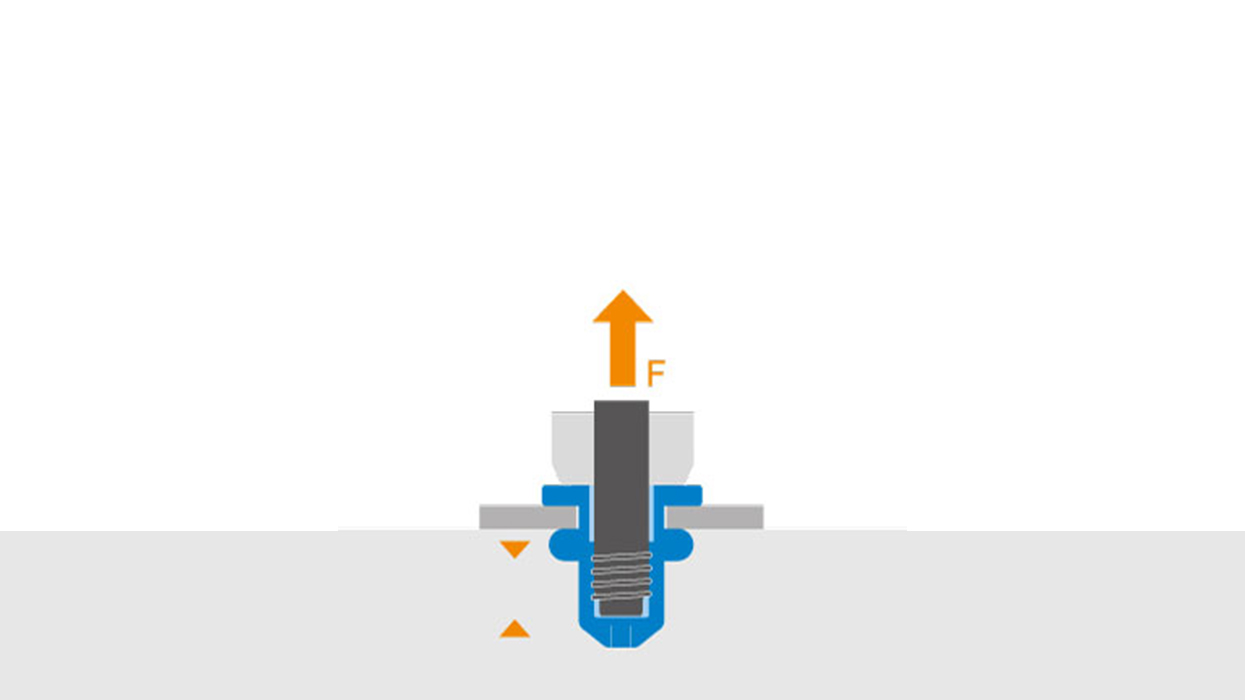

Phase 3: Retracting the threaded arbour & deforming the blind rivet nut

In the 3rd phase, the blind rivet nut is deformed. To achieve this, the threaded arbour is retracted to a predefined position without rotation. This tightens the nut, deforms it accordingly and forms a bulge. At WEBER, quality assessments are made by monitoring the pulling path of the blind rivet nut and the force generated during the process. Only pre-defined areas are permissible.

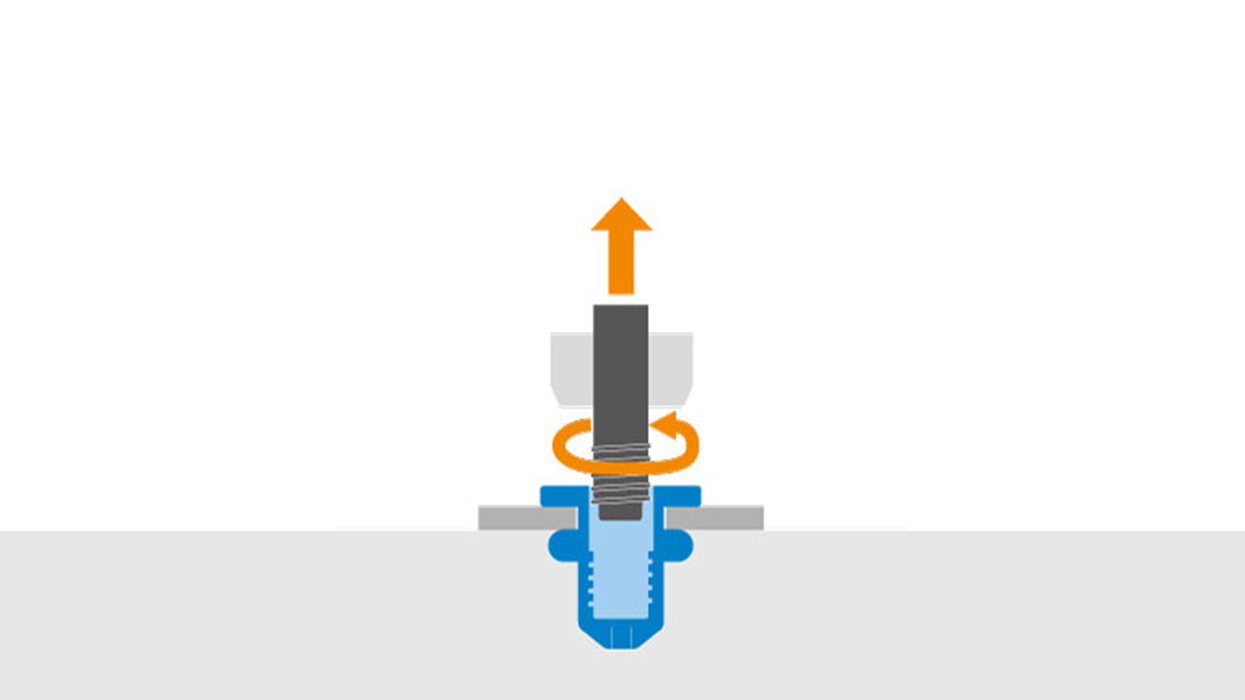

Phase 4: Removing the threaded arbour

Finally, the threaded arbour is removed. The process can start again. The next blind rivet nut can be fed already during the setting process.

Special features of the WEBER feeding system for blind rivet nuts

The special features of the WEBER feeding system for setting blind rivet nuts are the high output and the fast cycle times. With our perfectly automated process, the setting head works continuously while the next blind rivet nut arrives. The advantage of the WEBER inserting system over other setting systems is the precise alignment. Thanks to a highly precise pre-defined parameter, the setting system knows the correct positioning of the blind rivet nut and does not have to “search” along the pre-cut hole first.The WEBER setting system also uses precision monitoring systems. We check for damaged threads already during installation. This proactively avoids faults that only become evident afterwards with other installation systems.

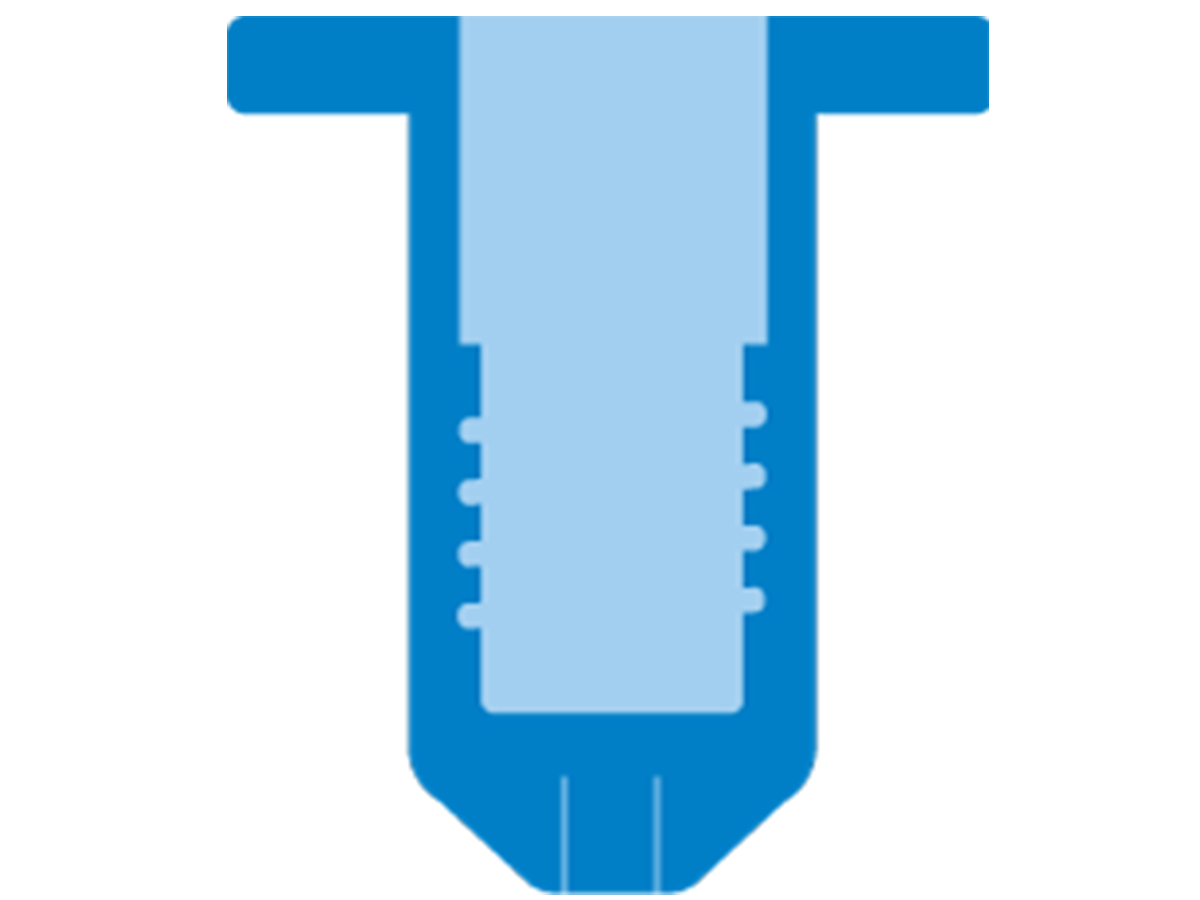

Structure of the WEBER setting unit

Get information about the structure of the WEBER setting unit in the e-mobility application area.

FAQ on blind rivets

What is the special feature of WEBER systems for the installation of hexagon nuts?

While other manufacturers turn the nut in their system until it is pulled into the pre-cut hole, WEBER focuses on precision installation. We define the precise position of the hole in advance so the blind rivet nut can be positioned correctly. The system does not have to “search” for the hole first.

What is the setting direction for blind rivet nut?

Blind rivet nuts can be set in any direction: horizontally or vertically (can also be mounted on a robot). The settings are made in advance.

Which forces occur during the installation of blind rivet nuts?

The force that has to be applied to produce the bulge during blind rivet installation is up to 25 kN (= deformation force).

Which blind rivet nuts are usually installed?

Blind rivet nuts that can be combined with the WEBER system typically have the following parameters.

Sizes: M4 to M10

Head diameter: up to 20mm

Length: up to 30mm

Material: Stainless steel, steel, aluminium

Shapes: round, hexagon

Of course WEBER can also work with custom items on request.

What is the difference between round and hexagon nuts?

The difference between round and hexagon nuts is in the shape and function. Blind rivet nuts with hexagon shaft offer a higher level of reliability because they can withstand a higher torque.

What is the structure of blind rivet nut installation?

The installation unit is either stationary or mounted on a robot or gantry.

Cycle times. How long does that take?

The cycle time depends significantly on the size and shape of the blind rivet nut, as well as the length of the thread.

With the WEBER setting unit for blind rivet nuts, cycle times as short as 6 seconds can be reliably achieved.

WEBER Schraubautomaten

WEBER Schraubautomaten GmbH is a family-run and innovative company that attaches great importance to the sustainable design of the value chain. The result is high-quality products with maximum process reliability that make production processes more efficient. Your success is our success.