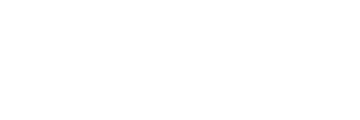

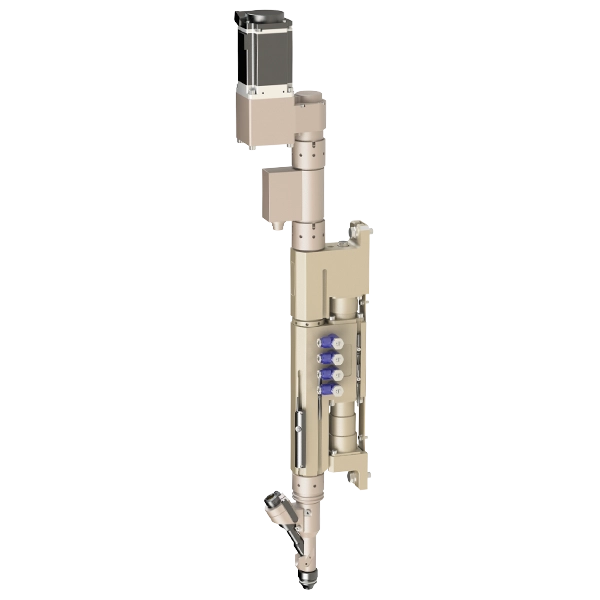

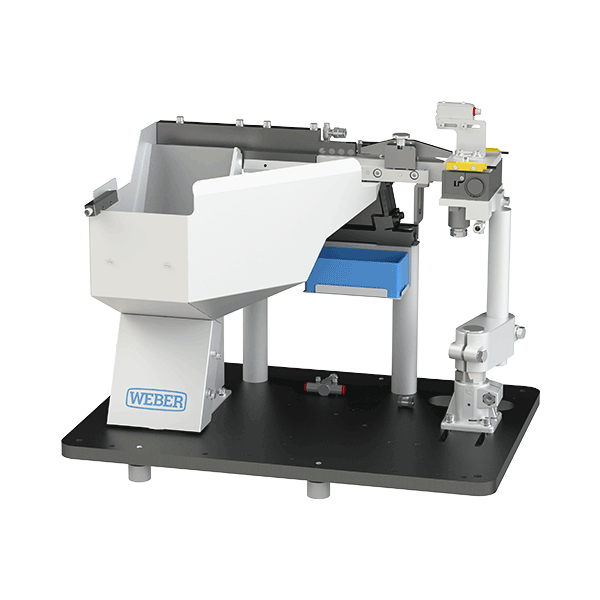

Fixtured screwdriver with flexible drive concept

Unparalleled flexibility is a shared feature of the fixtured screwdrivers SEB and SER. The modular design allows fast changeovers to other modules and drives. The screwdriving system SER features a screwdriver stroke – the head stroke is realized externally through a slide or robot. The screwdriving unit SEB additionally provides an integrated head stroke. SEB and SER are supplied with an automatic feed system.