The hopper (Belt driven refill hopper) can be mounted above both the vibratory bowl feeder and the step feeder. This addition will significantly extend refill intervals for the parts that will pass through the feeder. The discharge volume per time interval is infinitely variable – an optional fill level sensor is also available.

Feeding technology / Accessories

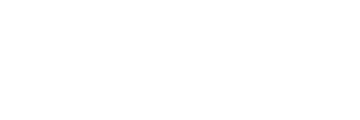

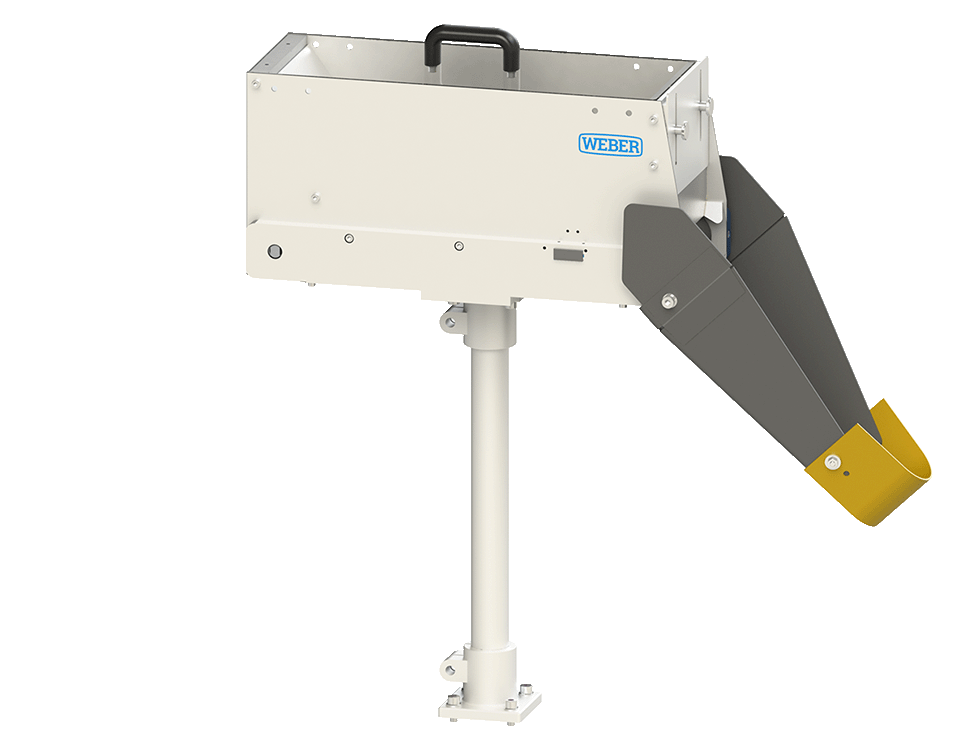

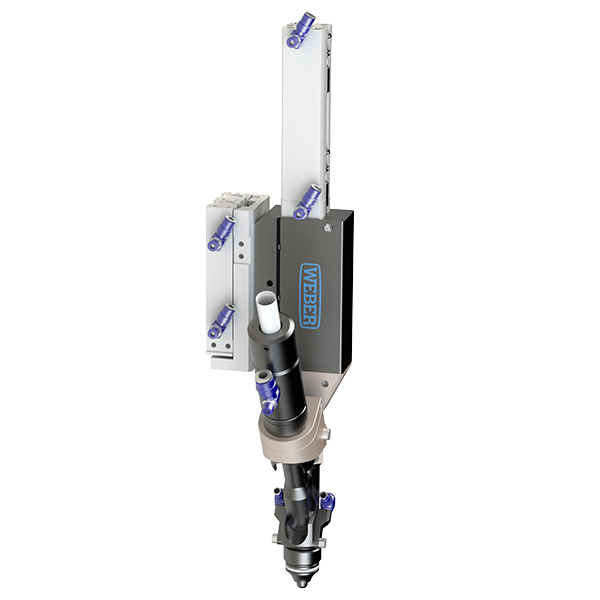

Refill hopper BB

The discharge quantity per time interval is infinitely variable – a level sensor is available as an option.

Features

24v drive for direct control via PLC

Level sensor

Adjustable bulk quantity

Plastic bulk with brake

Features

- Storage of feed items

- Extension of refill intervals (for operators)

- Folding top cover (optional)

- 24V drive for worldwide use

- Compact design

- Adjustable discharge amount

- Optional: Level sensor

Technical data Refill hopper BB

| Model | Length [mm] | Width [mm] | Height [mm] | Filling volume [L] | Max. Fill weight [kg] |

|---|---|---|---|---|---|

| BB-04 | 380 | 193 | 201 | 4 | 10 |

| BB-08 | 480 | 223 | 231 | 8 | 20 |

| BB-18 | 580 | 273 | 251 | 18 | 45 |

| Technical changes reserved. |

E-Catalogs

Discover solution and product information digitally. Take advantage of the WEBER E-Catalogs to quickly navigate to your destination. Everything at your fingertips, right here and now.

Downloads

You can find more information about the company and the products here. Discover WEBER automatic screwdriving machines GmbH and the world of assembly line automation.

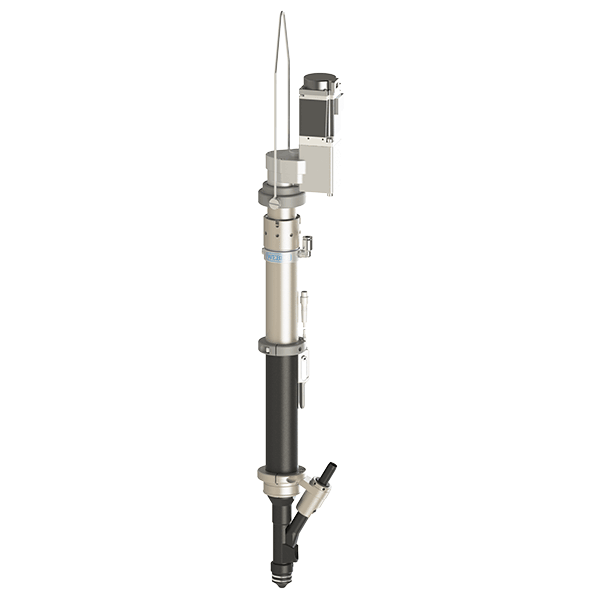

Suitable for feeding systems

Everything in one source

WEBER Schraubautomaten

WEBER Schraubautomaten GmbH is a family-run and innovative company that attaches great importance to the sustainable design of the value chain. The result is high-quality products with maximum process reliability that make production processes more efficient. Your success is our success.