As is well known, the whole is more than the sum of the individual parts. Hence also WEBER’s screwdriving systems grow with the requirements that companies impose on automated assembly processes. Fixtured screwdriving technology is used if connection processes are more complex, cycle times are shorter and quality requirements are higher. WEBER’s variably configurable fixtured screwdriving spindles adapt themselves to all screwdriving cases: whether mouthpieces, stroke lengths, sensors or drive units – WEBER offers tailor-made solutions depending on the task and screwdriving process. Nevertheless, the effort to change tools on the screwdriving units remains low – thanks to the tool-free change of the screwdriving head assembly.

Fixtured screwdriving systems

Our fixtured screwdriving systems overview

- With automatic feeding system for screws and pins

- Tool-free bit change

- With automatic feeding system for screws and pins

- For interference contours up to 150 mm

- Pick & Place screwdriver for lightweight robots

- Application for lightweigth robots

- Collaborative application (HRC) possible with the SEV-C

- Application for lightweigth robots

- For lightweight robots and coexisting HRC applications

- For shank-heavy screws

- With automatic feeding system for screws and pins

- For interference contours from 150 mm

- With automatic feeding systems for nuts and top-heavy screws

- For interference contours up to 150 mm

Further information on fixtured screwdriving technology

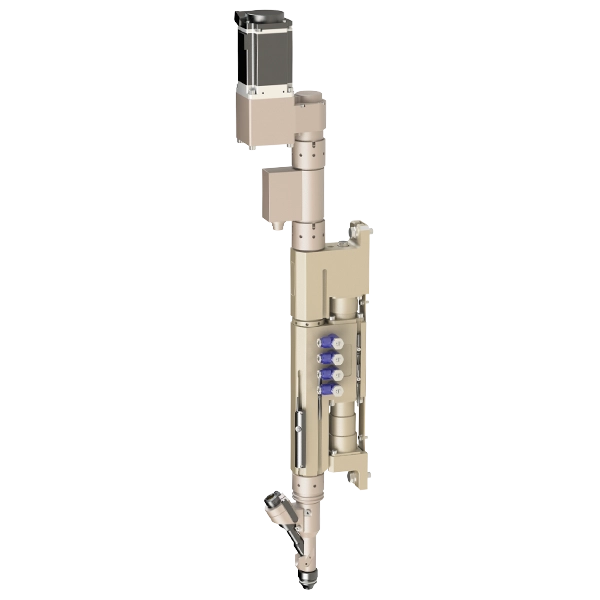

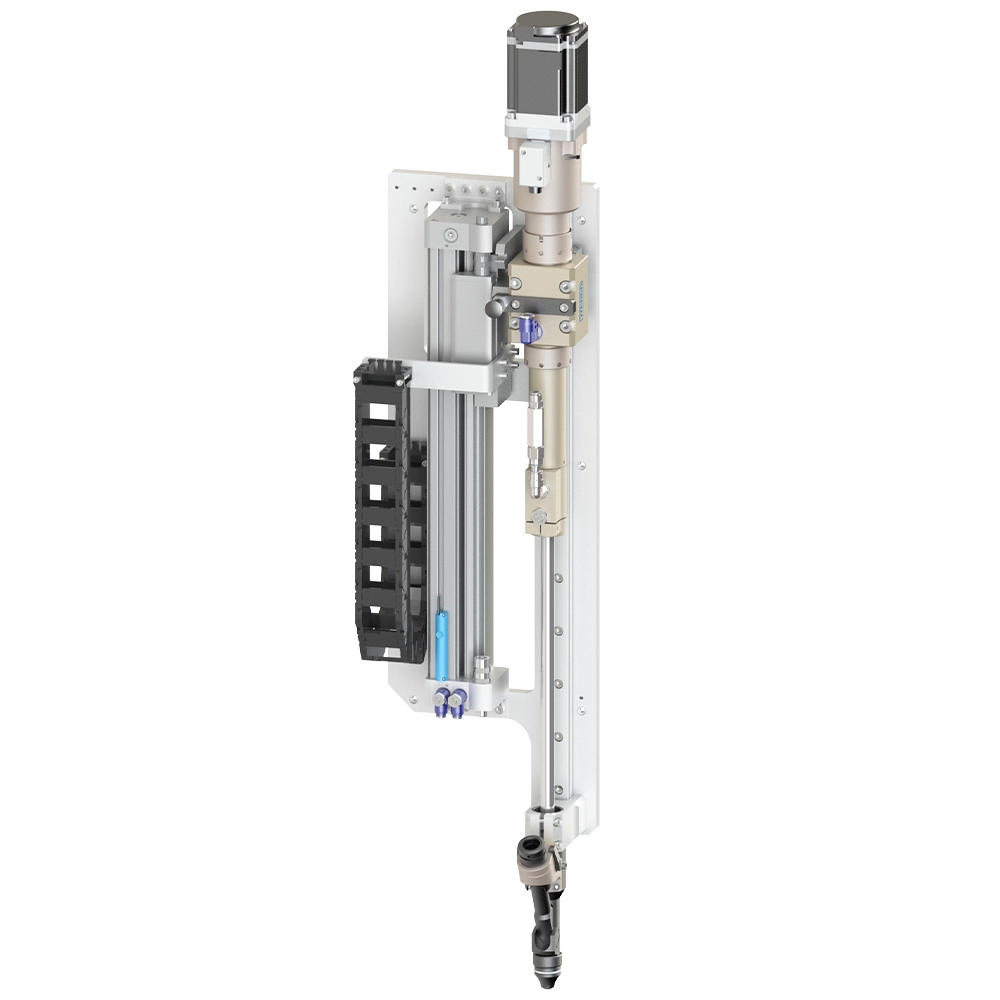

Fixtured screwdrivers SER / SEB

Flexibility is a shared feature of the fixtured screwdrivers SEB and SER. The modular design allows fast changeovers to other modules and drives. The screwdriving system SER has a screwdriver stroke – the SEB additionally has an integrated head stroke. SEB and SER are supplied with an automatic feed system.

Fixtured screwdriver SEV

The fixtured screwdriver SEV has a screwdriving spindle with vacuum technology. This allows process-reliable fittings at hard to reach locations. The closed design ensures exceptionally long service lives. The SEV is available with pneumatic drive or EC motor.

Fixtured screwdriver SEV-P

The SEV-P is a tightening screwdriver without automatic feed system, designed for pick & place applications. An expandable tool changing system allows a variety of different tools to be integrated, which can be used with different screwdriving programs as required. The great advantage lies in the option of fully automating assembly tasks for different fasteners

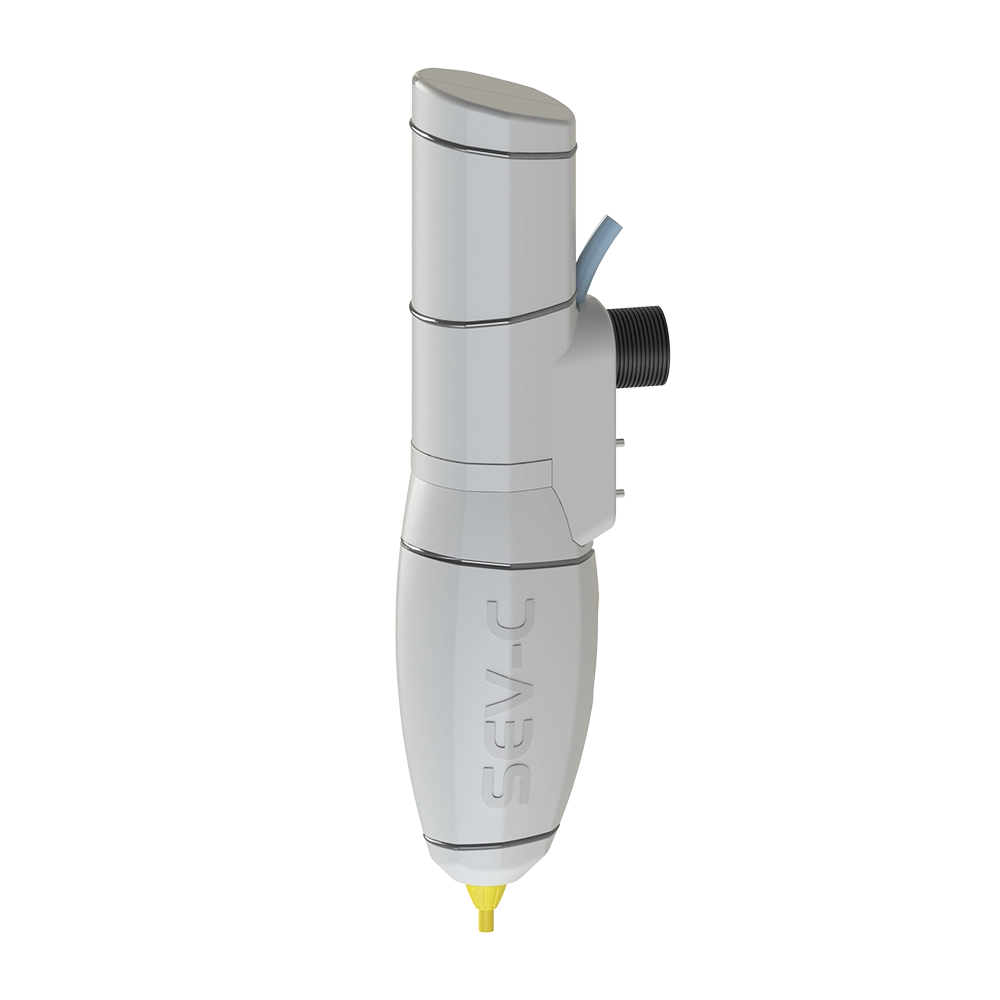

Fixtured screwdrivers SEV-C

Thanks to its low weight, the SEV-L HRC screwdriving system forms the basis for screwdriving with lightweight robots. The automated screw feed system enables short cycle times. On the SEV-C additionally uses a safety concept which allows collaborative working between humans and machines

Fixtured screwdriver SEV-L / SER-L

The screwdriving systems are used in conjunction with lightweight robots. The SEV-L additionally offers a vacuum function to reach low-lying or hard-to-reach screwdriving locations.

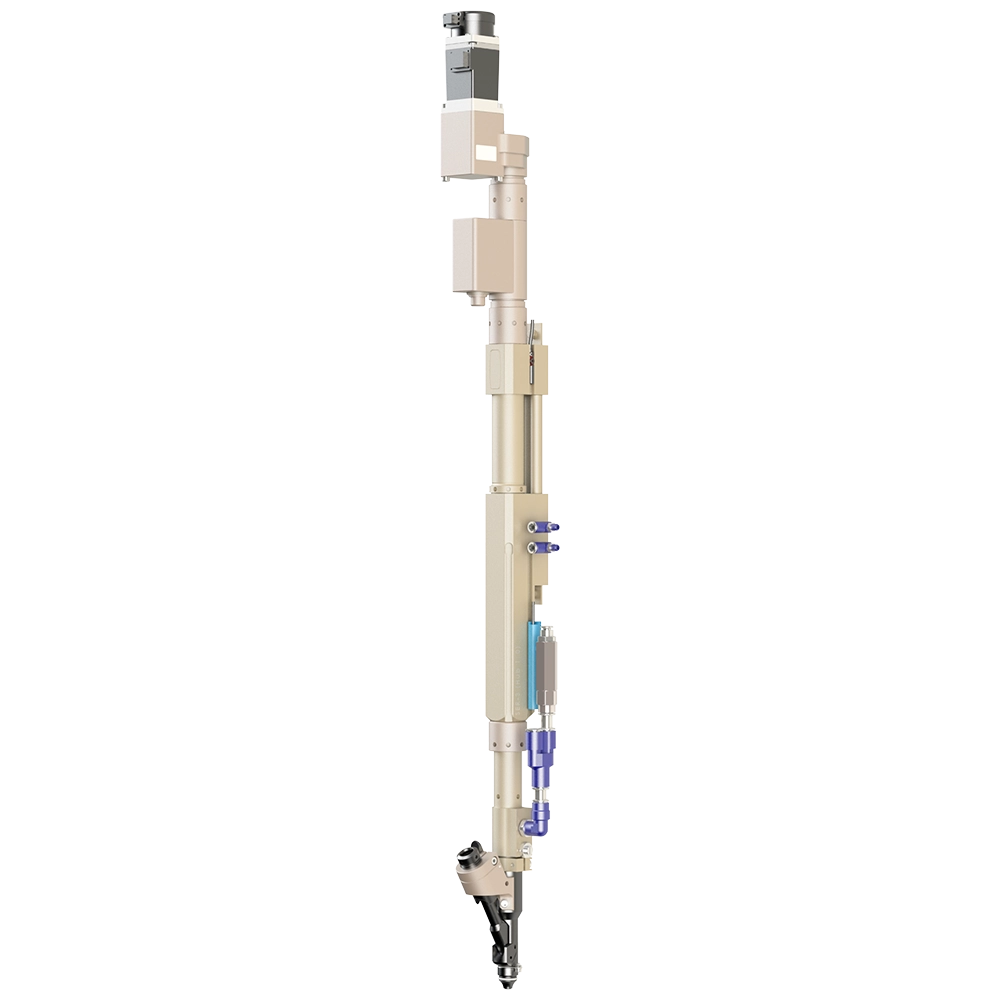

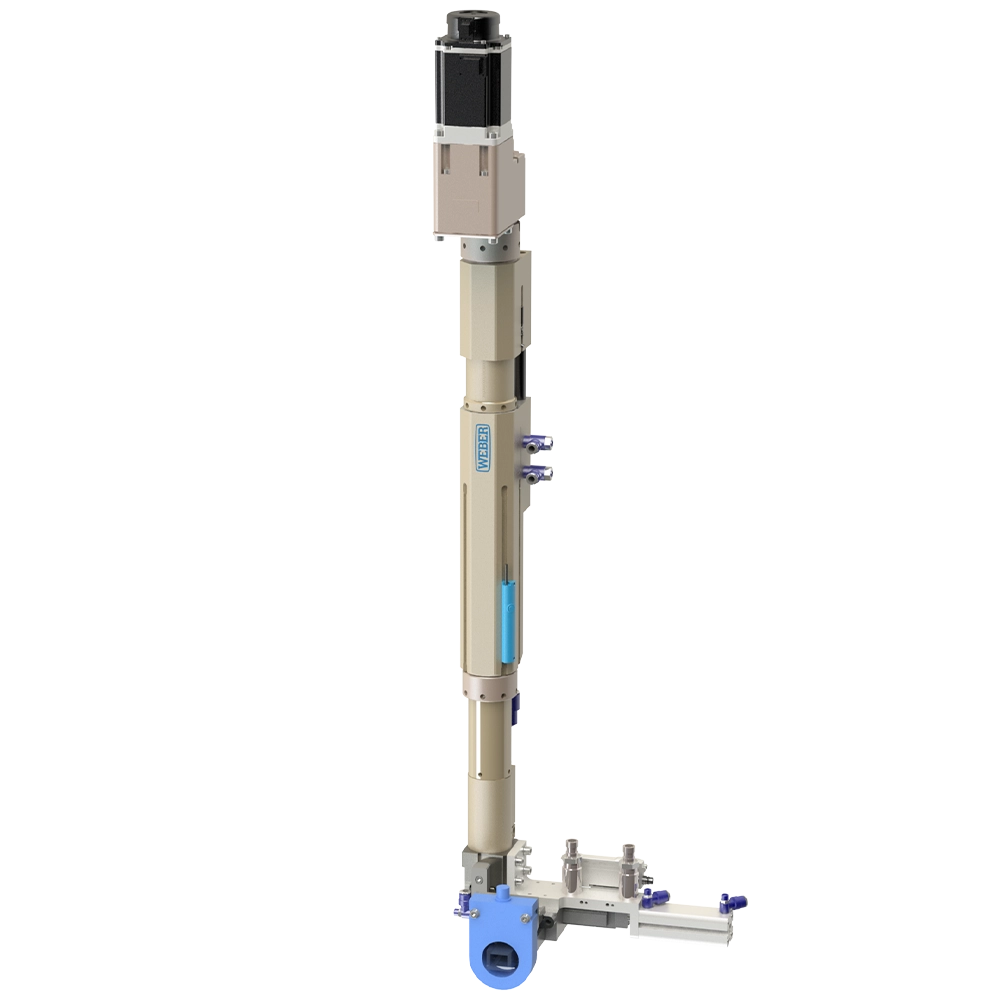

Fixtured screwdriver SEV-E

The screwdriving system is designed specifically to perform screw fittings at very hard to reach screwdriving locations using vacuum technology. Electronically controlled EC motors with integrated dynamic transducers can be supplied as well. On request, customer-supplied drives will be installed. Additional variability is achieved by various spindle models.

Fixtured screwdriver SEM / SEK

Similar to the handheld screwdrivers HSM/HSK, Weber offers the SEM and SEK models in the fixtured screwdriving range. The SEM variant is suitable for use with DIN-compliant nuts, flanges and special nuts. Top-heavy screws can be installed with the SEK. Both models use vacuum technology to reliably supply the fasteners.

Frequently asked questions about screwdriving systems!

What is the cycle time for a fully automated screwdriver with feed unit?

A cycle time of <1 s is possible for an automated screwdriving process. This is the “start – start” time, i.e. from start of screwdriving, through feeding of the new elements until “ready” for a new screwdriving process.

Which elements can be processed/screwed by a screwdriving station for fastening?

Screws, bolts, pins, nuts and much more. Is your element not listed here? Then please ask your local contact.

Where is fixtured screwdriving used?

Fixtured screwdriving from WEBER is used for complex joining processes with short cycle times and high quality requirements. These fully automated screwdriving units or screwdriving spindles become economically viable from approx. 60,000 screwdriving processes per year. The automation allows the high quality requirements for the screwdriving result to be met and reproduced. Areas of application can be found on the WEBER website, in the Applications section.

How fast does a screw move in the feed hose?

Die Geschwindigkeit ist abhängig von dem zu fördernden Element. Als Richtwert kann von einer Geschwindigkeit von 10 m/s ausgegangen werden.

How does a screwdriving system with an automatic screw feed system work?

On a complete screwdriving system consisting of feed unit and screwdriving unit, the screws can be filled into the feed unit as bulk goods. Different fixtures ensure that the fasteners are in the correct orientation and separate them with a separation unit – the escapement. From the escapement, one fastener at a time is blown towards the screwdriving unit through a feed hose. Depending on the screw geometry, an appropriate technology is used for transporting the screw into a mouthpiece (aligning guide). From there, the screwdriving unit can screw the fastener into the component.

What is a fixtured screwdriver?

A WEBER fixtured screwdriver is a screwdriving unit or screwdriving spindle which is not held and controlled manually, but mounted on a robot, axis system or stationary fixture. In combination with a feed system, this allows different fasteners to be screwed in within short cycle times.

WEBER Schraubautomaten

WEBER Schraubautomaten GmbH is a family-run and innovative company that attaches great importance to the sustainable design of the value chain. The result is high-quality products with maximum process reliability that make production processes more efficient. Your success is our success.