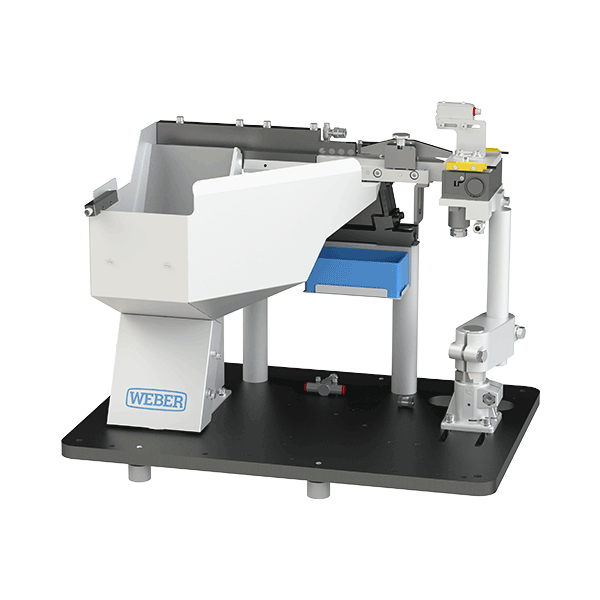

The “WEBER Principle” means fitting plus fully automatic feeding. Both our compact and powerful handheld screwdrivers and our widely configurable stationary screwdriving systems follow this principle. The automation of screwdriving processes has only one goal – to make assembly tasks quick, cost-efficient and reliable to contribute significantly to cost optimisation for the customer. The successful WEBER Principle consistently follows this strategy and ensures the economic success of our customers.

We set standards in fastener assembly automation with advanced feeding technology.

In principle it’s very simple

WEBER has been setting standards in the development and production of automatic handheld screwdrivers and stationary screwdriving systems for six decades. Over 400 employees worldwide ensure that this remains the case in the future. We promise! Automation processes in assembly are complex. The aim is to find solutions that meet a wide range of requirements and parameters. WEBER sees itself as a system specialist. The company not only develops manual and stationary screwdrivers, but also systems that are coordinated with each other and work together to achieve the desired increase in efficiency.

Technology That Connects

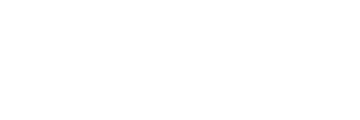

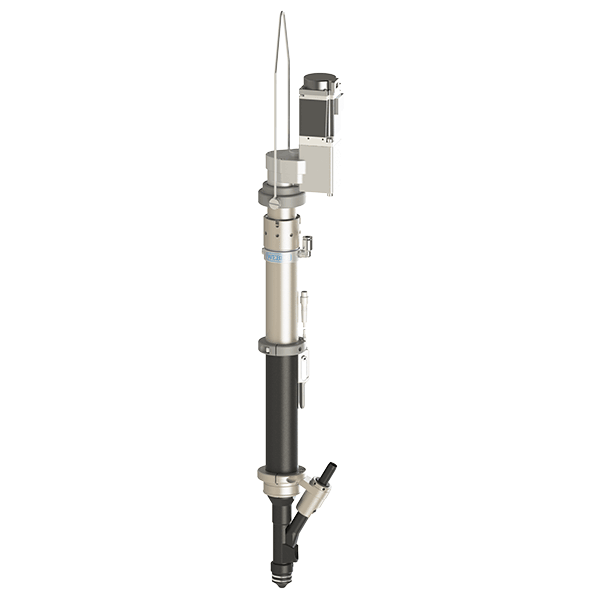

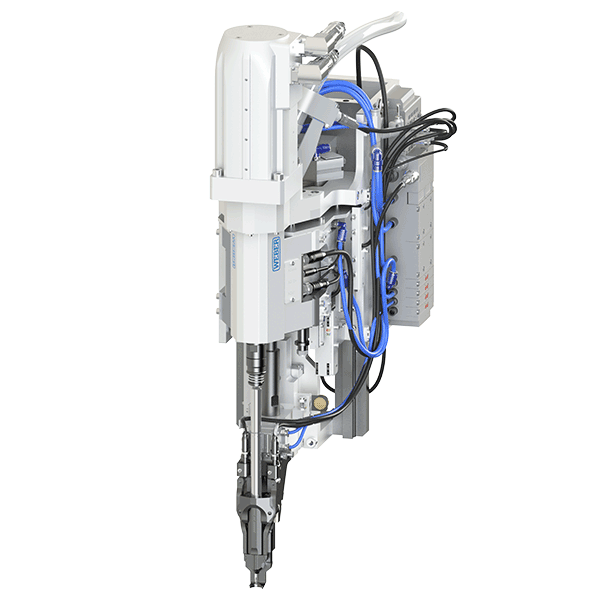

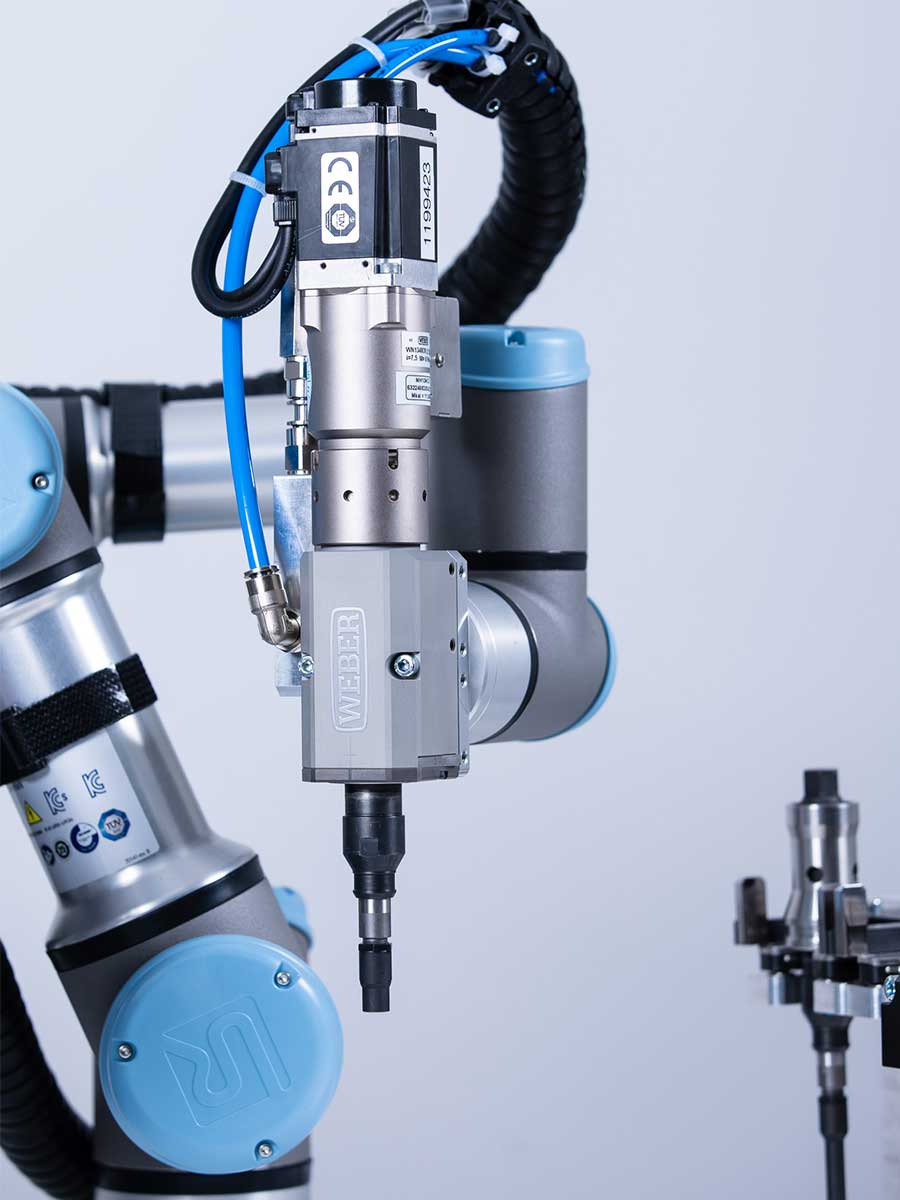

…the industry in processing and assembly. Our screwdriving controls, screwdriving and feeding prove their stability, flexibility and high effectiveness in large-scale industrial use at highly complex assembly stations or at efficiently operating individual workstations. Priority is given to being able to carry out the screwdriving process – realized by the manual screwdriving spindle, a stationary screwdriving unit, an automatic screwdriving machine or a screwdriving system – quickly and reliably.

Impressive technology – developed by us!

… and the automation of screwdriving processes has been our driving force for 60 years: WEBER Schraubautomaten GmbH in Wolfratshausen is one of the trendsetters in automation technology today, with manual and stationary screwdriving technology including feeders. We develop and manufacture electric handheld screwdrivers, automatic screwdrivers, screwdriving units and screwdriving systems – all tailored to the specific needs of our customers.

News

Trade fair dates

Frequently asked questions about WEBER Schraubautomaten GmbH?

Is documentation of a screwdriving operation necessary?

For screwdriving connections in the automotive, medical, aviation and household appliance industries, it is essential to document the assembly processes precisely due to guarantees, warranties and product liability.

Can joining technology be automated efficiently?

Screwdriving, blind riveting, setting and flow drilling are joining processes which are used with automatic feeding and enable short cycle times in the joining process.

What is an automatic screwdriver?

An automatic screwdriving machine (also called a screwdriving system) consists of a screwdriving spindle, feed system and control system and usually performs fully automatic, process-reliable and documentable screwdriving operations according to individual parameters.

What are the challenges of automated assembly in screwdriving technology?

The use of screwdriving systems suitable for series production requires the most uniform possible use of screws or other fasteners.

How do I automate screwdriving technology in assembly?

By using screwdrivers with automatic feeders in so-called assembly lines or production lines, higher quantities can be produced with precisely documented screwdriving processes and shorter cycle times at the same time.

WEBER Schraubautomaten

WEBER Schraubautomaten GmbH is a family-run and innovative company that attaches great importance to the sustainable design of the value chain. The result is high-quality products with maximum process reliability that make production processes more efficient. Your success is our success.