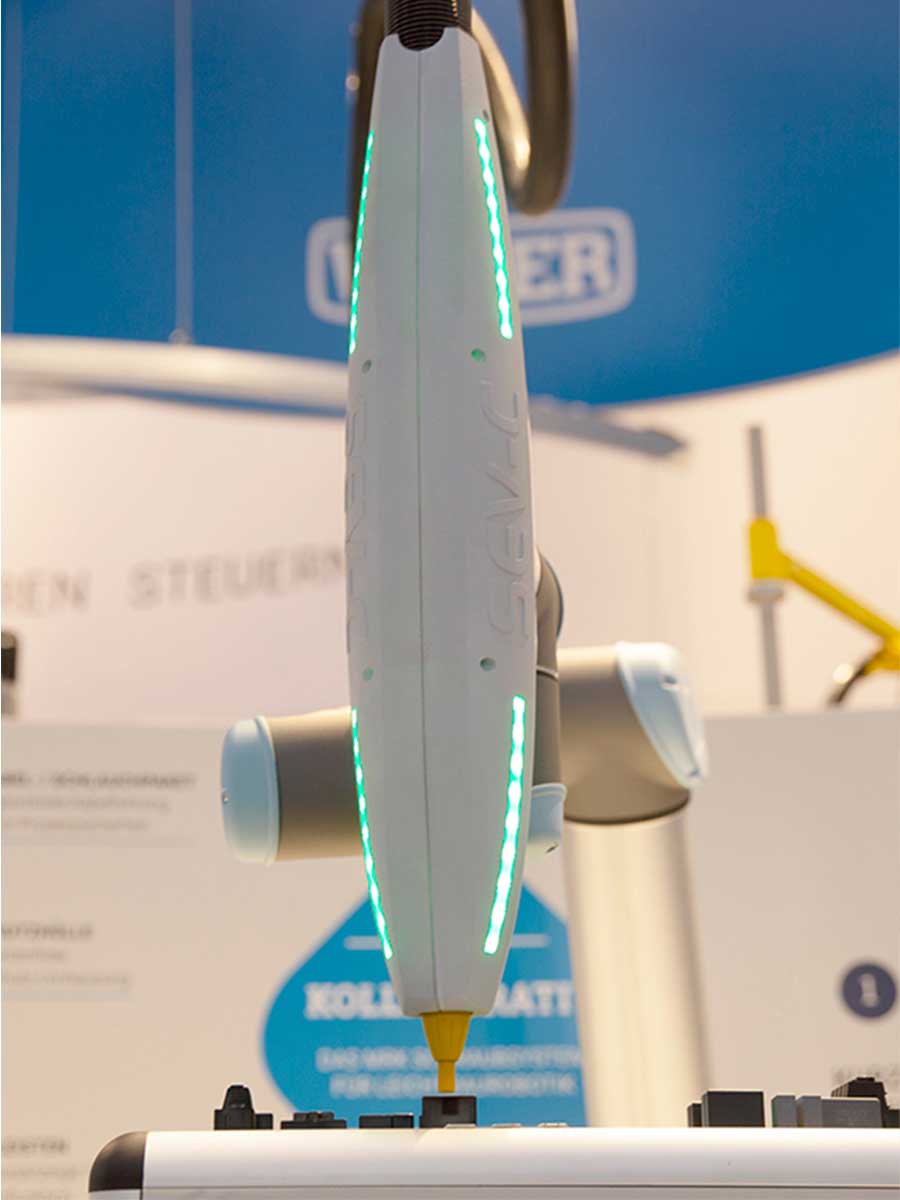

Wolfratshausen – WEBER Schraubautomaten GmbH is extremely satisfied with the results of this year’s “automatica” trade fair: With over 46,000 visitors (up 7 %) and 890 exhibitors (up 7 %) in attendance, this leading intelligent automation and robotics trade fair once again achieved record results. In particular, the 20 per cent increase in visitors from abroad is testimony to its increasing importance on a global level. The newly unveiled HRC screwdriving system SEV-C for use in human-robot collaboration that WEBER presented for the first time in Munich aroused the interest of trade visitors and resulted in numerous concrete customer inquiries and project concepts. Karl Bujnowski, Managing Director of WEBER: “These days, assembly processes often have to be completed in very confined spaces and involve complex environmental variables. Furthermore, developments in the collaborative interaction of humans and machines are also continuing. The HRC screwdriving system SEV-C is WEBER’s response to these questions about future screwdriving and connection technologies. Safety, efficiency and quality – all combined in one revolutionary screwdriving system.”

WEBER is paving the way for automated Human-robot collaboration screwdriving

The solution concept that WEBER presented to the public at “automatica” in the shape of the SEV-C allows for “unfenced” collaboration between humans and robots. Screwdriving processes are completed at the same time and in the same space. This means that as defined in ISO TS 15066, WEBER achieves the highest and most complex level of collaboration. Numerous customers and other interested parties took up the invitation to the product presentation at the WEBER trade fair stand. Work safety questions played a key role in the discussions. The new HRC screwdriving system SEV-C consists of a screwdriving spindle, automatic feed and an intelligent control unit. The system includes an innovative safety concept: + the SEV-C is surrounded by a rounded protective cover that is free of sharp edges + the nosepiece of the screwdriving spindle has a protective sheath and an integrated safety switch + all hoses, feed systems and sensors are routed in a closed cable package + clearly visible LED strips are installed on the side surfaces of the protective cover, indicating the system’s status and providing visual warning functions Furthermore, a universal adapter ensures that the SEV-C fits precisely and securely onto all common robot models. Bujnowski: “Our new screwdriving system SEV-C is testimony to WEBER’s decades of experience in the field of screwdriving and feed technology, particularly with regard to the construction of special machines. This means that we give the customer the possibility of realizing visionary assembly processes within the framework of a safe, collaborative human-robot workplace. Efficiency thanks to extremely short cycle times is the core promise that we give our customers. With the screwdriving system SEV-C, WEBER is paving the way for an ongoing expansion of the number of fields in which HRC technology is used. I’m pleased that at ”automatic” we were able to hold numerous discussions with potential users and that the first concrete project ideas have taken shape from these. The future of fully-collaborative and automated screwdriving processes began at the trade fair in Munich, if not before …”

We are happy to help you!

WEBER Schraubautomaten

WEBER Schraubautomaten GmbH is a family-run and innovative company that attaches great importance to the sustainable design of the value chain. The result is high-quality products with maximum process reliability that make production processes more efficient. Your success is our success.