Low noise emissions

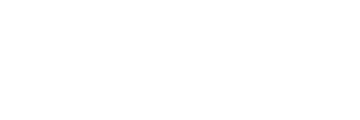

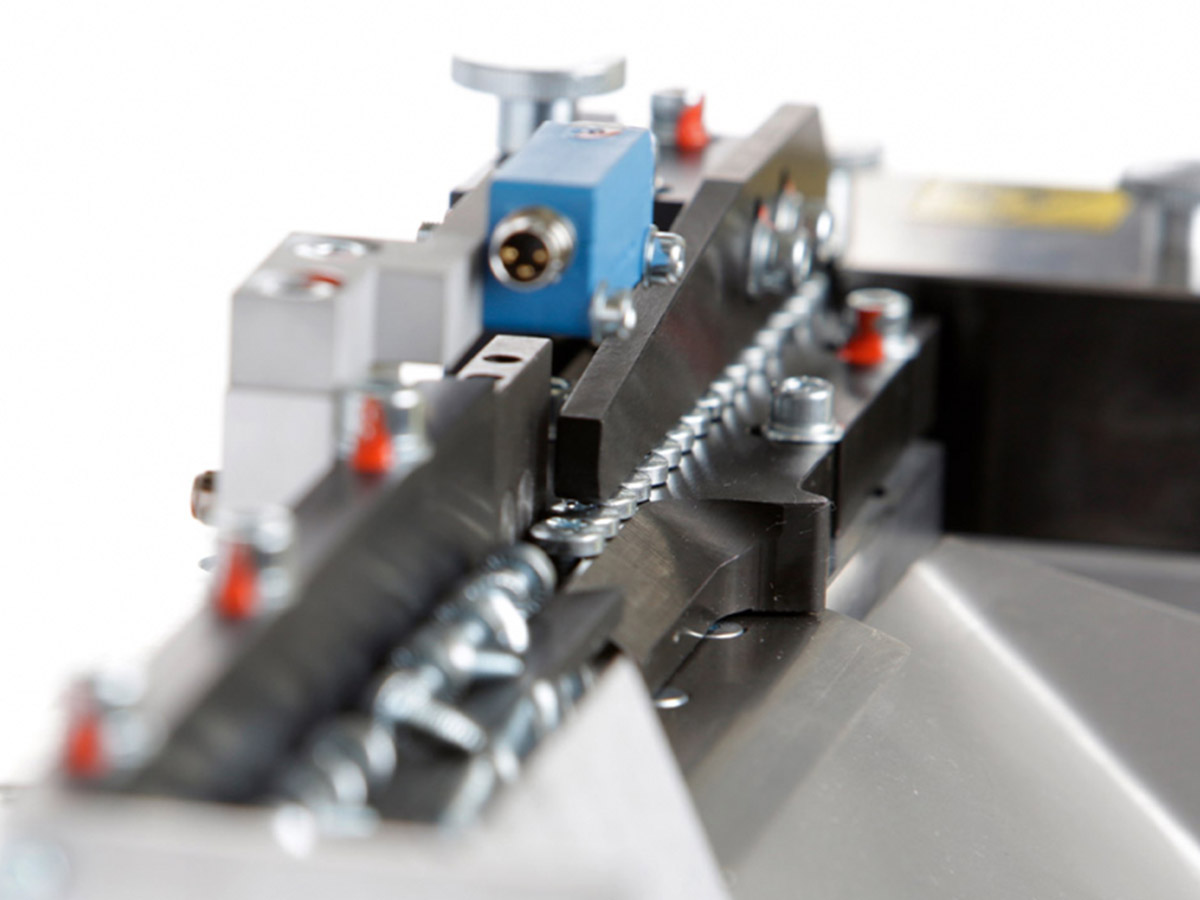

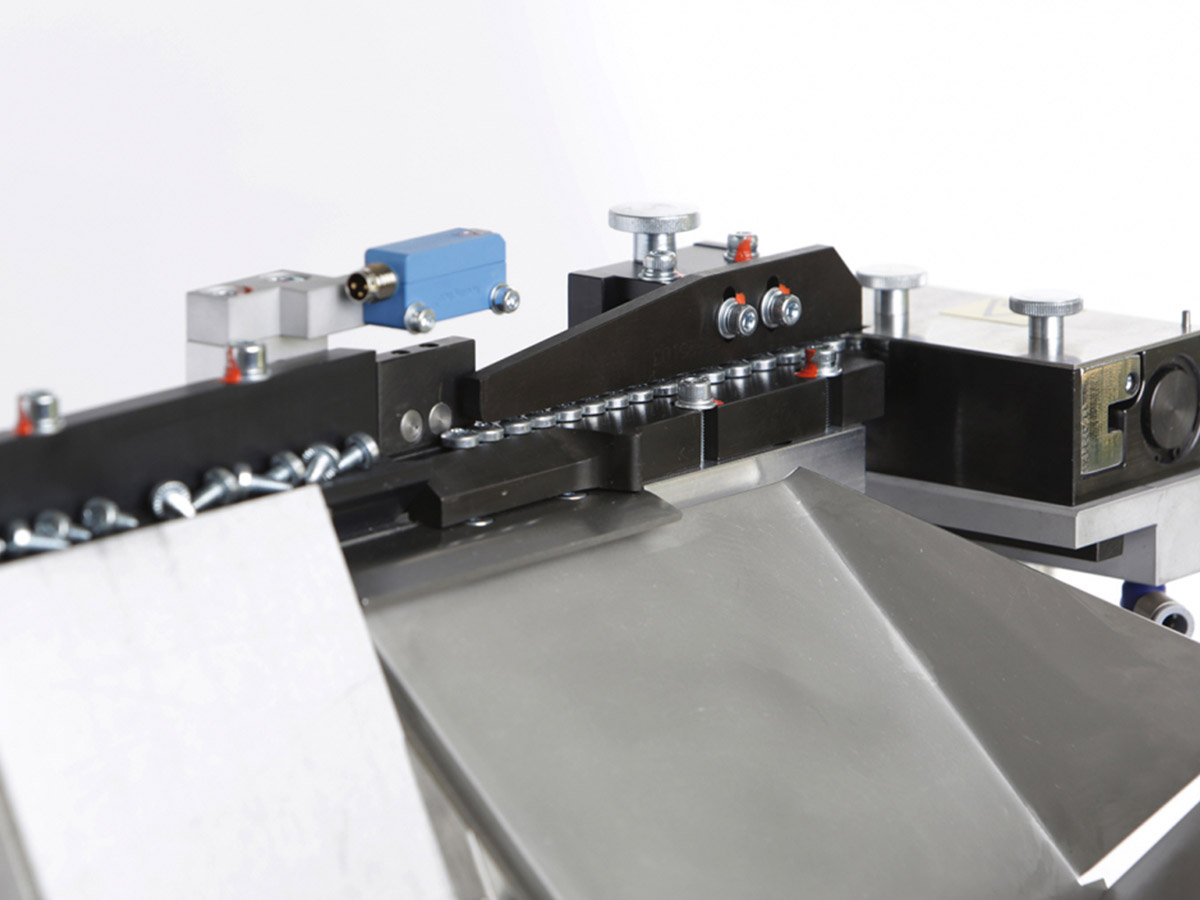

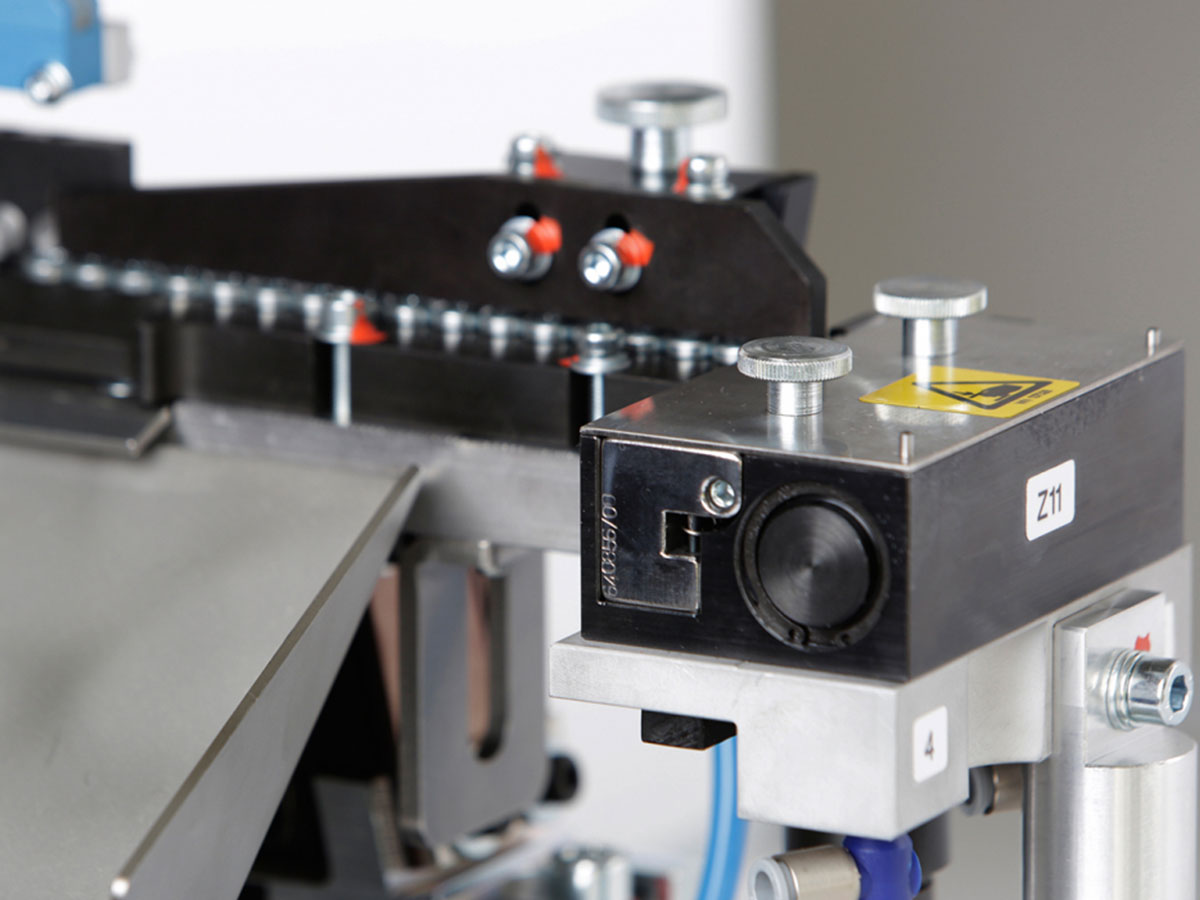

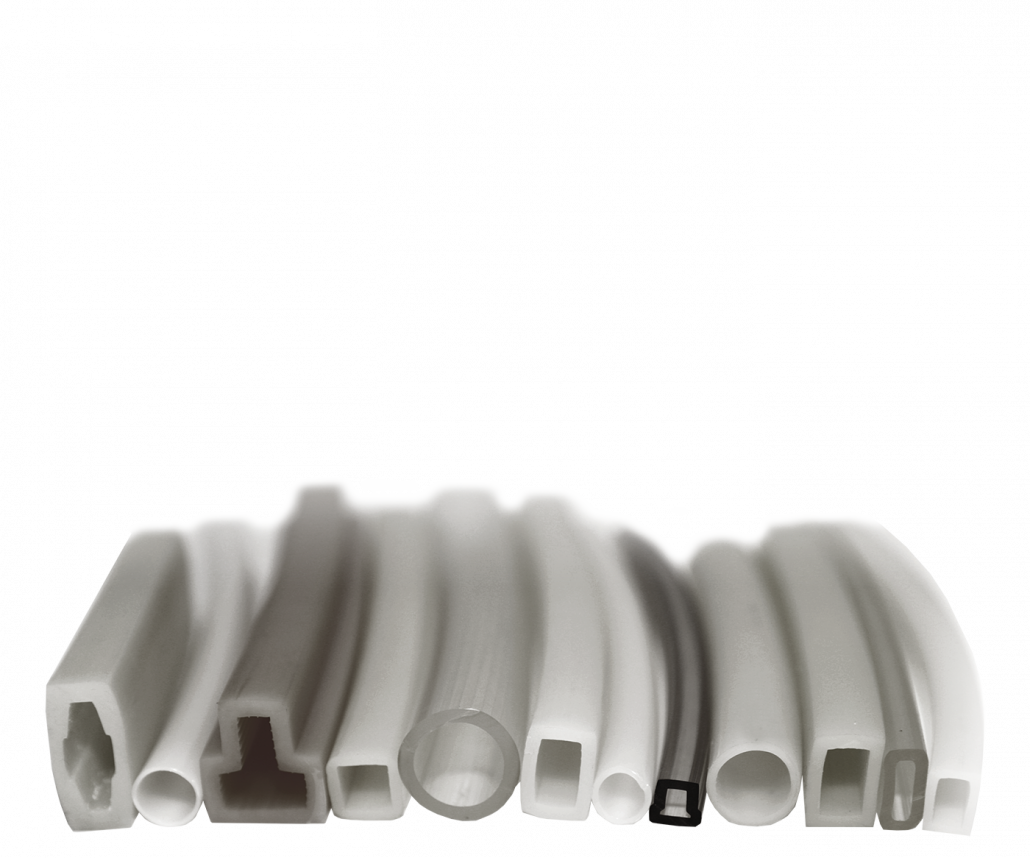

The ZEL feeds screws, nuts and pins and is gentle on the material. The system allows cycle rates as low as 0.8 seconds. A low-vibration outlet rail, which minimizes vibrations, enables processing of surface-coated and sensitive parts. This is a very important aspect particularly in terms of the requirements of technical cleanliness. Integrated sensors ensure high process reliability. The measures to reduce noise emissions are designed for noise protection at the workplace.